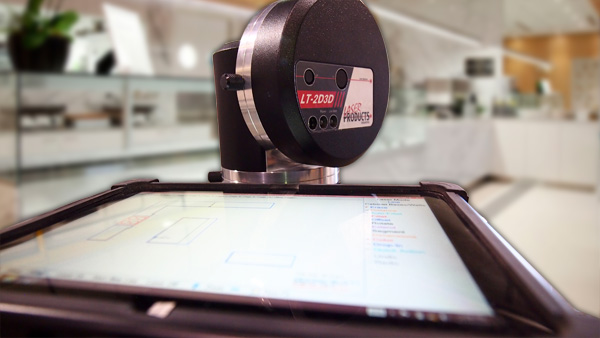

Our fabrication process starts with the Laser Products Industries LT-2D3D digital templating system. The accuracy of the system provides us with minimal tolerances and the scribing of the finished product to any surface. It eliminates the traditional template making process which is cumbersome, inaccurate, and requires a lot of space.

The Laser Products Industries LT-2D3D digital templating system

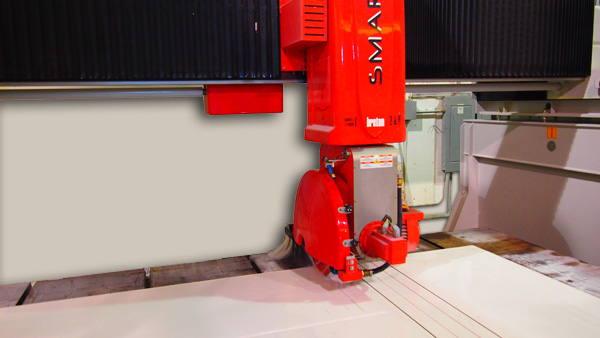

We then proceed to cutting on our recently imported equipment from Italy, the Breton Smart Cut 550 CNC saw.

The Breton Smart Cut 550 CNC saw for cutting stone products

This is a 5 axis digital CNC saw equipped with a high definition camera for digital imaging of slabs through the Breton patented slabsmith material management system. This provides a photographic layout of the counters which allows us to manipulate veining and seam layout. It also allows us to minimize material waste and provides an absolutely accurate cutting process whether we are dealing with wall scribing or mitering.

The next step in fabrication is the machining of edges, cut outs, and shapes on our brand new CNC work center.

The Park Industries Titan 2600 CNC work center for machining of edges, cut outs, and shapes

We use a recently installed Park Industries Titan 2600. This machine was built for us by the leading stone industry machine manufacturer Park Industries in St. Cloud, Minnesota. It is the most technologically advanced CNC machine available. It can produce a variety of edges as well as cut out sinks, core the tap holes, and polish edges to a very high standard. It also allows for material gauging and the cutting of any shape imaginable.

The Breton Easy Edge V7S mechanical polishing line

For back splashes and straight run products, we use a Breton Easy Edge V7S. It is a straight run mechanical polishing line which provides a deep luster polish with no deflection on the surfaces, usually occurring when a product is processed by hand.